Quibbles over Balance of Performance and accusations of sandbagging have been a near-constant feature of GT racing in recent times. Openly discussing the BoP isn’t permitted under the World Endurance Championship’s sporting regulations, but that’s not the only reason for grumbles being notably reduced this year as LMGT3 replaced GTE Am.

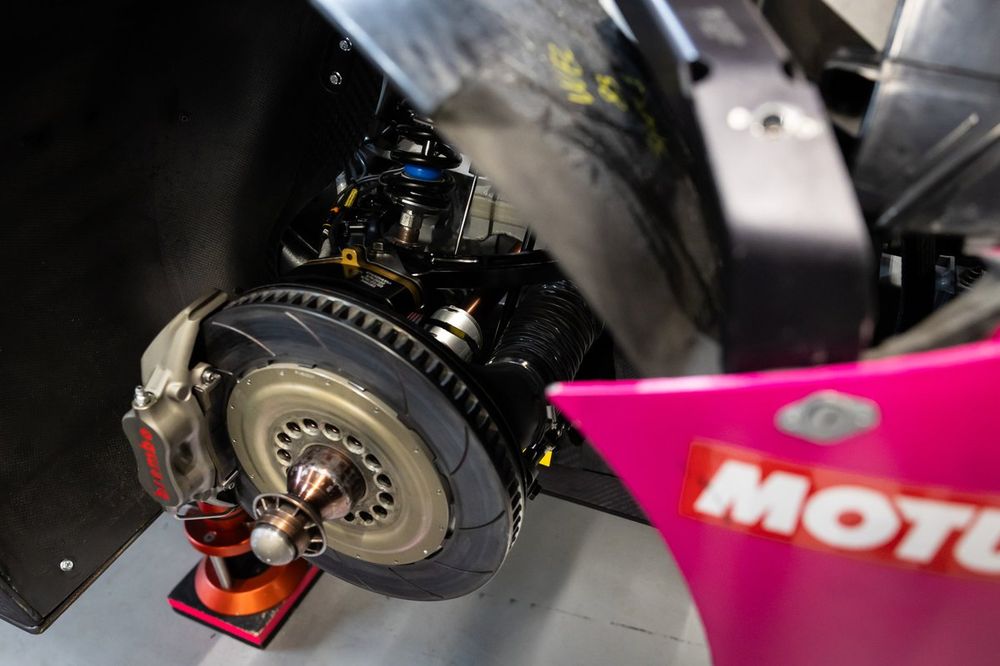

MagCanica is the FIA’s current supplier of torque meter sensors, which have been utilised since the outset of the Hypercar class in 2021 and have now migrated into the GT realm. Measuring torque from the driveshaft, they allow for live monitoring of power outputs so any spikes beyond what is allocated in the BoP are visible to the FIA and co-legislator Automobile Club de l’Ouest in real time. This is enforced by penalties, as seen with Toyota’s #8 Le Mans Hypercar at Spa in May.

Previously, efforts to achieve parity involved working with engine maps on the dyno, but the difficulty of covering all possible atmospheric conditions meant it was “more or less impossible to be very accurate”, according to the FIA’s chief technical and safety officer Xavier Mestelan Pinon. With the torque sensors, by contrast, he maintains it’s “the best way to have the right accuracy”.

By the same token, it eradicates any gains that can be made from sandbagging. Manufacturers can have no recourse to ask for BoP tweaks when the FIA can see exactly what power figures they are achieving.

“The crucial thing is to ensure you’re on your power target all the time, without going over and getting a penalty and without being under and being slow,” says Aston Martin Racing head of performance Gus Beteli. “To be always on top of it and get the best performance without getting a penalty, is challenging. The FIA will look at that data and see if you’re reaching the power or not. If you’re not reaching the power [limit], you’re slower.”

Efforts to get the sensors fully calibrated haven’t been the work of a moment. A process Beteli describes as “not easy” has been taxing even for manufacturers that can draw on prior expertise from Hypercar.

Torque sensors mounted on the driveshafts are now mandatory in the WEC’s LMGT3 class

Photo by: FIA

As well as leaning on sister GM brand Cadillac’s LMDh programme, Corvette already had experience of torque sensors from its C8.R GTE car, permitted to race in modified form against GT3 cars in the IMSA SportsCar Championship’s GTD Pro class with them installed. Ben Johnson, technical director of the Pratt Miller organisation that builds the Corvette Z06 GT3.R, says it was “still a learning curve, they’re very sensitive to the car that they’re on, how it takes the kerbs, how the engine reacts”.

But with more mileage, the slope has levelled out. For Johnson, efforts to “push it as far as you can, then bring it back to where you’re confident it’s going to be legal” have been finetuned to the point that, by Le Mans, Corvette was “confident to race from Test Day onwards”. Now a degree of maturity has been reached, manufacturers recognise that the greater accuracy and transparency resulting from torque sensors — with the FIA understood to have increased its headcount to manage and operate them — represents a step forward.

“It’s been a lot better than what it used to be in the past,” Beteli says. “Credit to the FIA and ACO, they’re doing a very good job with how they’re managing the performance and the data. We have meetings after every race to discuss.”

In years to come, the embrace of torque sensors could be regarded as an important development working for the good of a discipline that shows no signs of ceasing its upward trajectory

Mestelan Pinon describes torque sensors as “a very important tool” for not only upholding the BoP but also by controlling power output, disincentivising expenditure on new developments to keep costs controlled. “Clearly in WEC, it’s to avoid [manufacturers deciding] to develop a crazy technology regarding the internal combustion engine,” he says.

This purpose is served not only in the WEC, Mestelan Pinon points out: “We are working with Formula E, Formula 1 of course, in the very near future in cross country also” for Ultimate group entrants in the World Rally-Raid Championship. Adoption into the World Rally Championship from 2027 is also “on the table”.

However, although costs for WEC entrants are mitigated by no longer needing to submit to engine performance tests during the homologation process, he acknowledges that torque sensors are too expensive to be considered for grassroots series and reckons “honestly we don’t need that” outside professional championships.

Beteli agrees: “It’s an expensive piece of technology, not only buying the sensor and the driveshaft and all the development that goes into it. But as the technology evolves if you can get the price down so it’s accessible for everyone, it would be a benefit for sure.”

Torque sensors are likely to appear in more series too

Photo by: FIA

While cost remains a barrier to wider use, as Mestelan Pinon admits “it’s not something which is really cheap”, steps have been made on reliability. Software developed since the 2023 Algarve WEC round, when a sensor failure on the #7 Toyota forced it into a pitstop for repairs, would result in a different outcome from a repeat scenario. “In each situation we have something to manage it to be sure that we don’t ask a car to stop,” says Mestelan Pinon.

For the time being, its impact is largely hidden from view, and Mestelan Pinon recognises that a large majority of fans simply want to see a fight between drivers. “A lot of them don’t care” how it is achieved, he says, which fits a desire for technology “to be in the back office and not on the front office”. But in years to come, the embrace of torque sensors could be regarded as an important development working for the good of a discipline that shows no signs of ceasing its upward trajectory.

“It may operate behind the scenes,” says Johnson, “but the fans and all the stakeholders then get the benefit of much closer racing, which is good for the sport and everybody involved.”

Its impact may not be seen, but WEC manufacturers have welcomed the introduction of torque sensors into LMGT3

Photo by: Shameem Fahath